In case you missed it, here are some highlights, via a slideshow, from DMG MORI's Innovation Days in Chicago. There was so much to see and learn about!

#leadership#fiveaxis#amerimold

- Dmg Mori Chicago Innovation Days San Francisco Tree Service

- Dmg Mori Chicago Innovation Days San Francisco Tree Lighting 2020

- Dmg Mori Chicago Innovation Days San Francisco Tree Andy Goldsworthy

- Dmg Mori Chicago Innovation Days San Francisco Tree Pruning Schedule

- Dmg Mori Chicago Innovation Days San Francisco Tree Removal Permit

DMG MORI announced its strategic direct-to-customer approach in October and Innovation Days 2016 made the company's plan to establish 28 Technology Centers across the USA a centerpiece of the event. Dr. Mori, who spoke during Innovation Days to a full house, said all of the Technology Centers will be open by the end of this year.

In the “Open Innovation Area”, we must set the expectations of all of our suppliers, proactively new ideas or innovative services on the DMG MORI platform. The aim here is highlight innovations at an early stage and try to safeguard competitiveness. Purchasing is responsible for this process. DMG MORI Chicago Innovation Days May 13 th – 16 th, 2019 Monday to Thursday, 9 am – 5 pm Register now. Technology Excellence.

DMG MORI provided this kiosk for Innovation Days guests to use to locate their local Technology Center and Application and Service Engineers who will provide support and respond quickly to service requests.

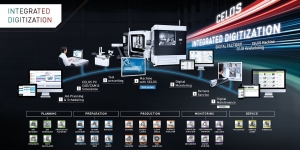

During Innovations Days in Chicago, industry experts gave presentations on the latest trends in manufacturing, including topics such as IIoT, or the Industrial Internet of Things, and how DMG MORI's exclusive CELOS control can help users network their machines using digital technologies and the internet.

DMG MORI is a worldwide leader of cutting machine tools for turning and milling, as well as a comprehensive supplier in additive manufacturing using powder nozzle and powder bed. DMG / Mori Seiki USA has announced the annual Innovation Days event will take place at the company’s Headquarters and Chicago Solution Center on May 8 – 10, 2012 where progressive machine technology will combine with the latest tooling, automation, software, training and application strategies.

This Lasertec 65 3D from DMG MORI attracted quite a crowd during Innovation Days, and it's no wonder given that it is a hybrid, all-in-one, five-axis CNC mill with the capability to do laser-deposition welding with integrated milling.

Dmg Mori Chicago Innovation Days San Francisco Tree Service

A look inside the Lasertec 65 3D shows the laser deposition process, which uses a powder nozzle that DMG MORI says is 10 times faster than the powder-bed process with no need for supporting structures. Laser and milling options are dynamically exchanged, and allows more flexibility with geometries and milling applications.

A very large control panel, which strongly resembles a laptop computer, is displayed to provide a glimpse of how user-friendly DMG MORI's controls are for its machines.

This is simply a photo of the DMG MORI Davis, California, facility but during Innovation Days in Chicago, guests were able to don a special mask and take a virtual reality tour!

One of two DMG MORI machines to make their US debut is this CTX gamma 2000 TC. With a diameter of eight inches, the length of the compactMASTER spindle has been reduced by 2.8 inches so that it now measures only 17.7 inches – all with a 120 percent higher torque. The interplay of the 5.9-inch larger X-axis (-1 / +30.5 in.) and the 0.8-inch longer Y-travel of ± 8.3 inches brings an enormous gain in freedom for users.

DMG MORI's premium motorsport sponsorship and technology partnership with the Porsche Team was well-represented during Innovation Days. Porsche has installed an in-house automotive component production facility using DMG MORI CNC technology.

PreviousDmg Mori Chicago Innovation Days San Francisco Tree Lighting 2020

NextRead Next

DMG MORI recently hosted Chicago Innovation Days 2016, welcoming customers, industry partners and other guests into its Hoffman Estates, Illinois, facility to tour the 42,000-square-foot showroom and see live demonstrations of 33 of the company’s machining centers, including US premiers of its SPRINT 32 I 5, SWISSTYPE machine and CTX gamma 2000 TC Second Generation turn-mill machine.

Visitors also saw DMG MORI’s new customer hospitality area, and attended daily seminars during which industry experts discussed the latest trends in advanced machining technology, Industry 4.0 and how digital technologies are and will continue to influence manufacturing worldwide. On the same note, DMG MORI also offered guests a virtual tour of its Davis, California, location!

Take a few minutes to view our slide show of the Hoffman Estates facility and visit us.dmgmori.com to learn more.

RELATED CONTENT

Machining Molds with Negative Stock Shutoffs

Negative stock shutoff can help you make better molds in less time. Here is a clear definition and description of the process. While the concept is fairly simple, the implementation can be challenging.

How to Justify New Machine Tool Technology

A look at some of the factors influencing the success of your machining center investment.

New Developments in High-Speed Machining Technology

In the last two years, there have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Dmg Mori Chicago Innovation Days San Francisco Tree Andy Goldsworthy

#fiveaxis#leadership

DMG MORI demonstrated the latest trends and innovations in machine tool manufacturing during its Chicago Innovation Days.

Read Next

DMG MORI demonstrated the latest trends and innovations in machine tool manufacturing during its Chicago Innovation Days. The annual event took place on May 13-16 at the company’s Hoffman Estates, Illinois, location.

In the spotlight were machines and auxiliary equipment, including the CELOS app-based control and user interface that DMG MORI introduced in 2013, that promoted “open connectivity” through integrated digitization. DMG MORI announced that it is increasing its portfolio of CELOS services with intelligent software solutions and connective hardware. Open connectivity includes digital IoT services and products to integrally network processes and machines with one another. Additionally, DMG MORI has established the CELOS Club, which offers customers unique solutions on their path to Industry 4.0 and IIoT.

Dmg Mori Chicago Innovation Days San Francisco Tree Pruning Schedule

The company also debuted its compact ALX 2000 turning machine and also compact DMP 70 five-axis machining center to the U.S. market during Innovation Days. The ALX 2000 is being manufactured at the company’s Davis, California, plant.

Another focus at the event was five-axis excellence – complete machining for more productivity. DMG MORI says five-axis machining was initially an answer to the trend towards increasingly complex work pieces. Today, it is increasingly becoming part of productive mass production in many industries, including aerospace, automotive, medical, and tool and mold making sectors. The company displayed a representative cross-section of its five-axis portfolio, including a DMU 50 3rd Generation automated with a PH 150 pallet handling, two monoBLOCK machines and two models from the duoBLOCK series as well as the DMU 200 Gantry. The ULTRASONIC 20 linear and the LASERTEC 3D machines for additive manufacturing complete the 5-axis exhibits.

Emphasis was put on automated machines being crucial components of a digital factory and therefore an integral part of intelligent and networked production. On display with the ALX 2000 was the GX 7 gantry loader, for example. Additionally, DMG MORI demonstrated the NHX 4000 with a RPS for 21 pallets and the NHX 6300 with a LPP for twelve pallets. Further examples of efficient automation solutions were the Robo2Go 2nd Generation for a wide variety of turning centers and the DMP 70 with WH 3 workpiece handling.

Dmg Mori Chicago Innovation Days San Francisco Tree Removal Permit

Finally, DMG MORI has been involved in the growing field of additive manufacturing for more than 20 years. The company has five Additive Manufacturing Excellence Centers (AMEC) worldwide. It also holds a 30% share in software developer InTech, which has provided key software and technological expertise for generative production. A first result of this collaboration is the new Optomet software, which InTech offers for the Lasertec SLM series machines. It has self-adjusting and learning algorithms that calculate the required parameters of the SLM process in advance within minutes.

RELATED CONTENT

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

New Developments in High-Speed Machining Technology

In the last two years, there have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.